Hard science in Disney's teddy printer

Engineers at Disney Research Labs have made some improvements on their fabric-based 3D-printer, which can churn out anything from a blanket to a teddy bear.

Engineers at Disney Research Labs have made some improvements on their fabric-based 3D-printer, which can churn out anything from a blanket to a teddy bear.

“Today's 3D-printers can easily create custom metal, plastic, and rubber objects,” said Jim McCann, associate research scientist at Disney Research Pittsburgh.

“But soft fabric objects, like plush toys, are still fabricated by hand. Layered fabric printing is one possible method to automate the production of this class of objects.”

Printing in fabric presents particular cutting and handling challenges, however, which the Disney team has addressed in the design of its printer.

The latest soft printing apparatus includes two fabrication surfaces - an upper cutting platform and a lower bonding platform.

Fabric is fed from a roll into the device, where a vacuum holds the fabric up against the upper cutting platform while a laser cutting head moves below.

The laser cuts a rectangular piece out of the fabric roll, then cuts the layer's desired 2-D shape or shapes within that rectangle.

This second set of cuts is purposefully left incomplete so that the shapes receive support from the surrounding fabric during the fabrication process.

Once the cutting is complete, the bonding platform is raised up to the fabric and the vacuum is shut off to release the fabric.

The platform is lowered and a heated bonding head is deployed, heating and pressing the fabric against previous layers.

The fabric is coated with a heat-sensitive adhesive, so the bonding process is similar to a person using a hand iron to apply non-stitched fabric ornamentation onto a costume or banner.

Once the process is complete, the surrounding support fabric is torn away by hand to reveal the 3-D object.

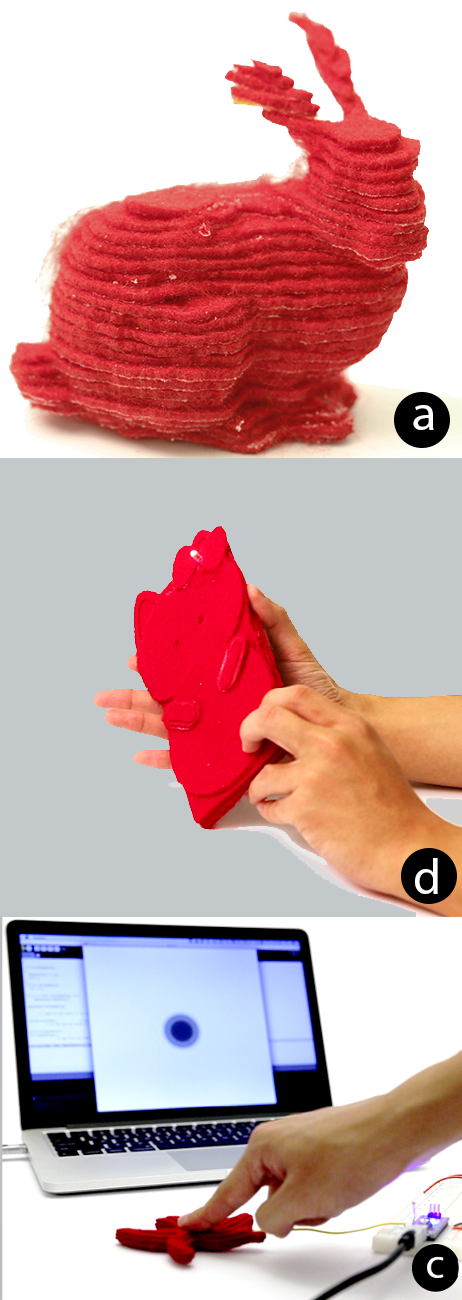

The researchers demonstrated this technique by using 32 layers of 2-millimetre-thick felt to create a 6cm tall bunny. The process took about 2 and a half hours.

The team has also demonstrated the possibilities of using the printer to implant electronic sensors in fabric.

They are even working on a fabric smartphone case with an antenna that can harvest enough energy from the phone to light an LED.

Print

Print