Ore-sorting gets tech edge

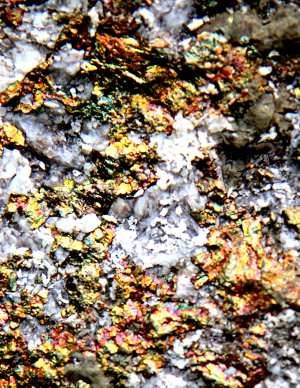

CSIRO scientists have created a device that can identify and sort copper ore.

CSIRO scientists have created a device that can identify and sort copper ore.

Taking advantage of magnetic resonance technology, the analyser rapidly identifies ore grade so that large volumes of waste rock (gangue) can be rejected before it enters the plant, significantly reducing the amount of energy and water needed for processing.

The analyser is available to the international copper market through NextOre, a new company created by RFC Ambrian, Advisian Digital and CSIRO.

“Bringing the analyser to market through NextOre opens up the opportunity to transform the global copper industry and reduce its environmental footprint,” CSIRO research director Nick Cutmore said.

“NextOre has identified 59 mature copper mine sites where the analyser could be applied to extend their life, capturing 35 per cent of global copper production.

“The solution could also enable undeveloped, low grade mines to be brought into production, so the economic benefits are huge.”

By illuminating batches of ore with short pulses of radio waves, magnetic resonance penetrates through copper ores – much like medical MRI “sees” into human bodies – to rapidly and accurately detect ore grade.

It has an advantage over other ore sorting analysers that can often only go skin deep to detect mineral particles on the surface of ore, producing less reliable results.

While the productivity benefits vary depending on the characteristics of the orebody, the analyser has the potential to more than double average ore grades once sorted.

It could represent as much as a 20 per cent reduction in processing costs in some copper mines.

In its first year, NextOre will focus its efforts on engaging the South American and Canadian market.

“Contracts have been secured to provide magnetic resonance analysers to three companies, including two top-tier producers, in the coming financial year,” NextOre CEO Chris Beal said.

“We are providing full ore sorting solutions, including technical and engineering advice, to move from concept to site trials and final implementation.”

In addition to copper, the magnetic resonance analyser can be applied to gold and iron-bearing ores.

Print

Print